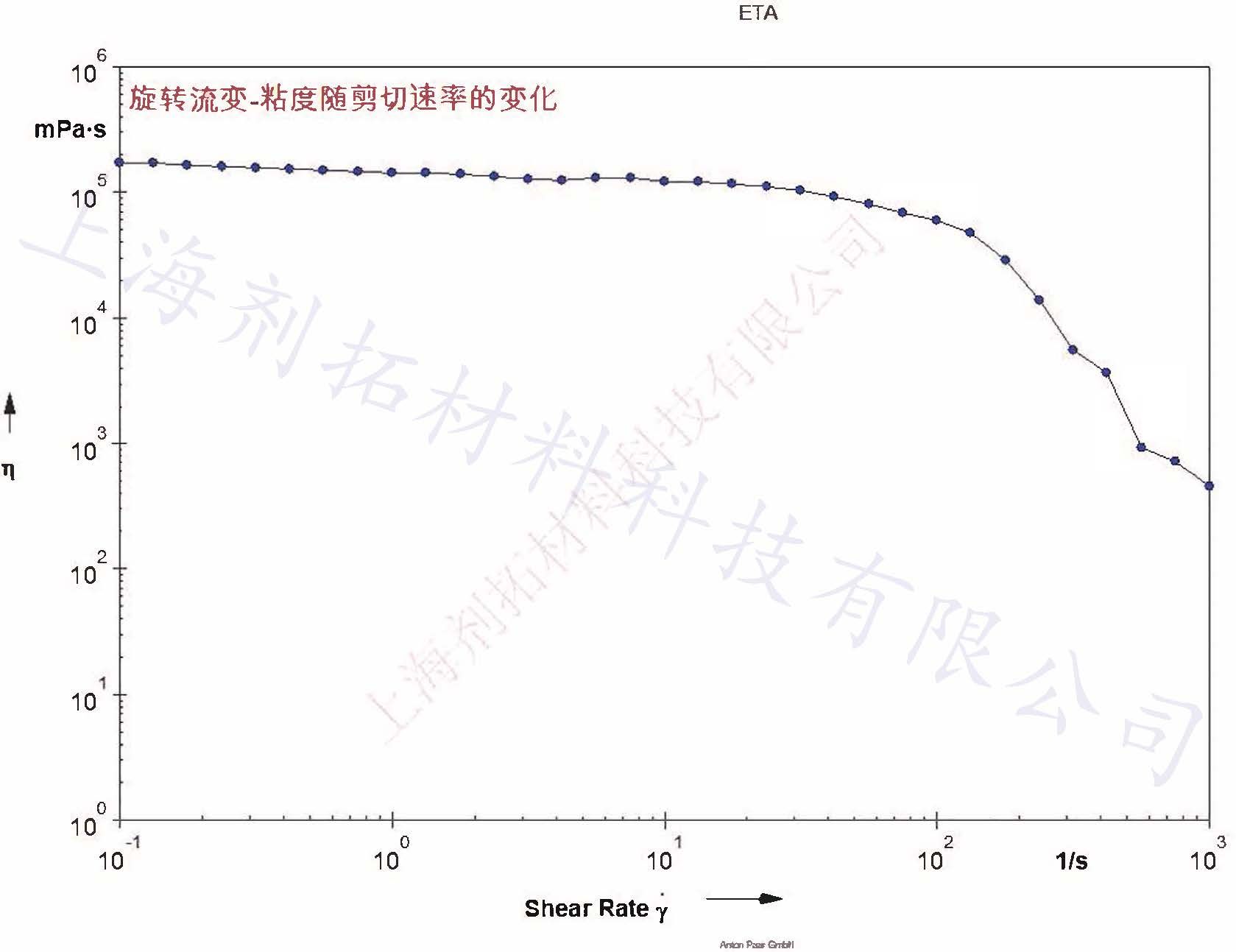

Capillary rheometer testing for thermoplastic polymer materials includes measuring the change of viscosity with shear rate, stress-strain curves, plasticization curves, as well as determining the temperatures of softening point, melting point, flow point, etc.

Principle of Capillary Rheometer

- The capillary rheology system extrudes polymer materials through a die of known size at a precisely controllable volume flow rate, thereby characterizing the fluid properties of the material under high load (high pressure) or high shear rate.

Instrument Model:

- Netzsch Rosand RH10

Instrument Technical Parameters

- Temperature range: Room temperature ~ 400℃

- Speed range: <1200mm/min

- Temperature accuracy: ± 0.1℃

- Barrel diameter: 15 mm

- Die diameters: 0.5, 1.0, 1.5, 2.0 mm

Sample Submission Requirements and Packaging

- Sample: 300g of granular plastic sample.

- Samples should not contain low-boiling solvents or water.

- Samples must not crack, explode, volatilize, or produce highly toxic gases within the test temperature range; otherwise, the instrument will suffer irreversible damage.

Testing Example