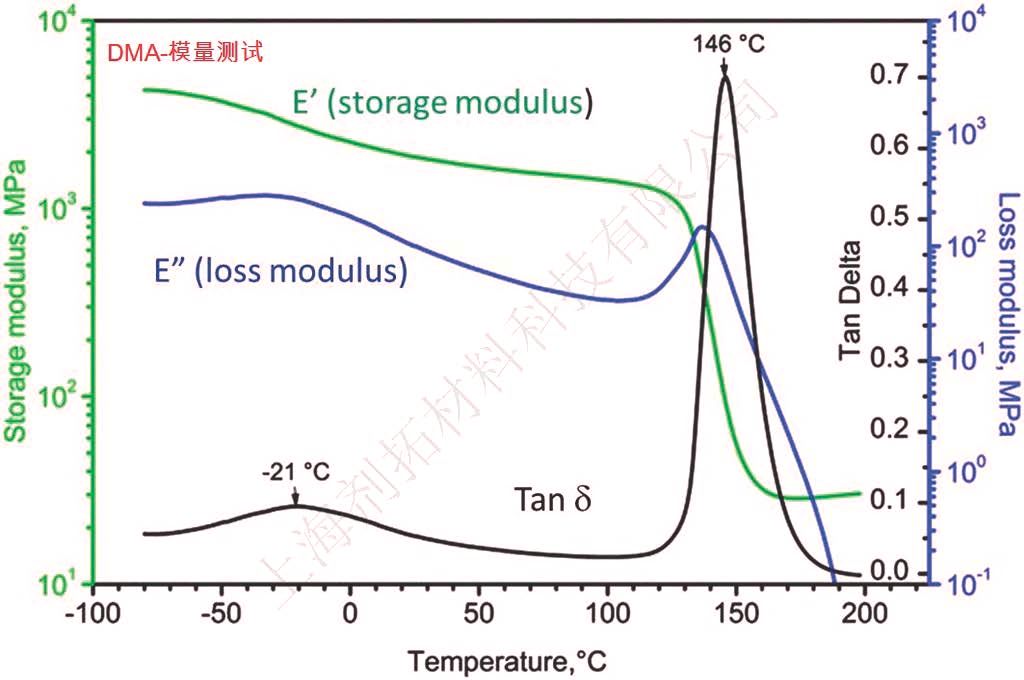

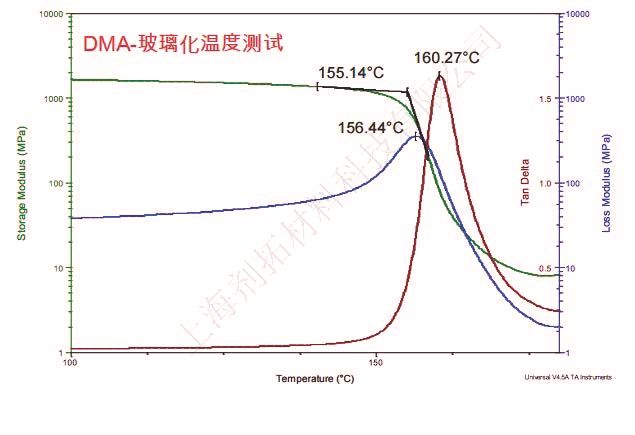

Dynamic Mechanical Analyzer (DMA)

Dynamic Mechanical Analyzer (DMA) is a technology that studies the dynamic mechanical properties of materials by measuring the deformation response under dynamic alternating loads in relation to temperature, frequency, or time. The core of DMA involves analyzing the elastic behavior (storage modulus) and viscous behavior (loss modulus) of materials under periodic stress or strain, as well as the ratio of the two (tanδ), to reveal properties such as glass transition temperature (Tg), damping characteristics, mechanical relaxation behavior, and thermal stability.

Instrument Model and Technical Parameters

- Instrument model: TA Q850, USA

- Technical parameters:

- Temperature range: -100 to 500°C

- Temperature accuracy: ± 0.01°C

- Heating rate: 0.1 to 50°C/min

- Frequency: 0.1 to 100 Hz

- Atmosphere: Air

Sample Submission Requirements and Packaging

- 2–3 specimen strips

- The sample must not decompose, soften, or melt within the test temperature range to avoid irreversible damage to the instrument.

###Material Mechanical Property Testing Modes and Parameters

| Testing Mode | Specimen Size (Length × Width × Thickness) | Modulus Type | Applicable Materials | Supplementary Notes |

|---|---|---|---|---|

| Tension | 30 | Young's Modulus | - Rigid/soft rubbers (e.g., polyurethane, soft PVC)- Common engineering plastics (e.g., PE, PP, rigid PVC) | Suitable for linear elastic materials under uniform stress; clamp gripping methods must prevent specimen slippage. |

| Three-point Bending | 50 | Flexural Modulus | - High-rigidity materials: engineering plastics (e.g., PC, epoxy resin), metals, ceramics, composites | Commonly used to evaluate the flexural stiffness of structural materials like plates and pipes; the span is typically 80% of the specimen length. |

| Single/Double Cantilever | 35 | Flexural Modulus | - Medium-rigidity materials: engineering plastics (e.g., nylon, ABS), rigid rubbers | Suitable for testing crack propagation or fracture toughness; single cantilever is often used for single-edge notched specimens, while double cantilever offers better symmetry. |

| Shear | 40 | Shear Modulus | - Soft rubbers, elastomers (e.g., natural rubber, silicone rubber, EVA) | Special shear fixtures are required to avoid interference from tensile or compressive forces; results reflect the material's resistance to shear deformation. |

Key Terminology Notes:

- DMA parameters:

- Storage modulus (elastic component, E')

- Loss modulus (viscous component, E'')

- Tanδ = E''/E' (damping factor)

- Test precautions:

- "Specimen strips" refer to standardized test samples; ensure dimensions match the testing mode.

- For temperature-sensitive materials, provide thermal stability data in advance to avoid instrument damage. |

Testing Cases

Testing standrad

- ASTM D4065 Standard Practice for Plastics: Dynamic Mechanical Properties ASTM D5023 Standard Test Method for Plastics: Dynamic Mechanical Properties in Flexure

- ASTM D5418 Standard Test Method for Plastics: Dynamic Mechanical Properties in Compression

- ASTM D7028 Standard Test Method for Glass Transition Temperature (Tg) of Polymer Composites

- ISO 6721-1 Plastics — Determination of dynamic mechanical properties — Part 1: General principles

- ISO 6721-5 Plastics — Determination of dynamic mechanical properties — Part 5: Flexural vibration

- ISO 4664-1 Rubber — Determination of dynamic properties — Part 1: General guidance

- GB/T 33061.1-2016 Plastics — Determination of Dynamic Mechanical Properties — Part

- GB/T 33061.5-2020 Plastics — Determination of Dynamic Mechanical Properties — Part 5: Flexural Vibration Method

- GB/T 9870.1-2006 Rubber — Determination of Dynamic Properties — Part 1: General Principles