Product Overview

Ecure-08, Ecure-01, and Ecure-20 series are modified alicyclic amine curing agents designed for demanding industrial applications requiring exceptional chemical resistance and fast curing properties. These low-viscosity amine-based curing agents are ideal for use in environments exposed to harsh chemicals, oils, and extreme temperatures.

Key Features

- Excellent Chemical Resistance: Resistant to a wide range of chemicals, including acids, bases, solvents, and industrial oils.

- Low Viscosity: Ensures easy mixing and application, even in complex geometries.

- Low Exotherm: Minimizes heat buildup during curing, reducing the risk of thermal stress and cracking.

- Anti-Amine Blush & Oil Resistance: Forms a smooth, non-yellowing surface even in humid or oily conditions.

- High Gloss Finish: Provides an aesthetically pleasing and durable surface finish.

- Excellent Compatibility: Fully compatible with epoxy resins, ensuring homogeneous curing without phase separation.

Applications

- Industrial Coatings: For chemical storage tanks, pipelines, and processing equipment.

- Industrial Flooring: Resistant to heavy machinery, chemicals, and abrasion.

- Corrosion-Resistant Linings: For pipes, vessels, and structures exposed to harsh chemicals.

- Ultrafiltration Membrane Potting: For industrial wastewater treatment systems.

- Epoxy Composites: Fast-curing matrix for fiber-reinforced composites.

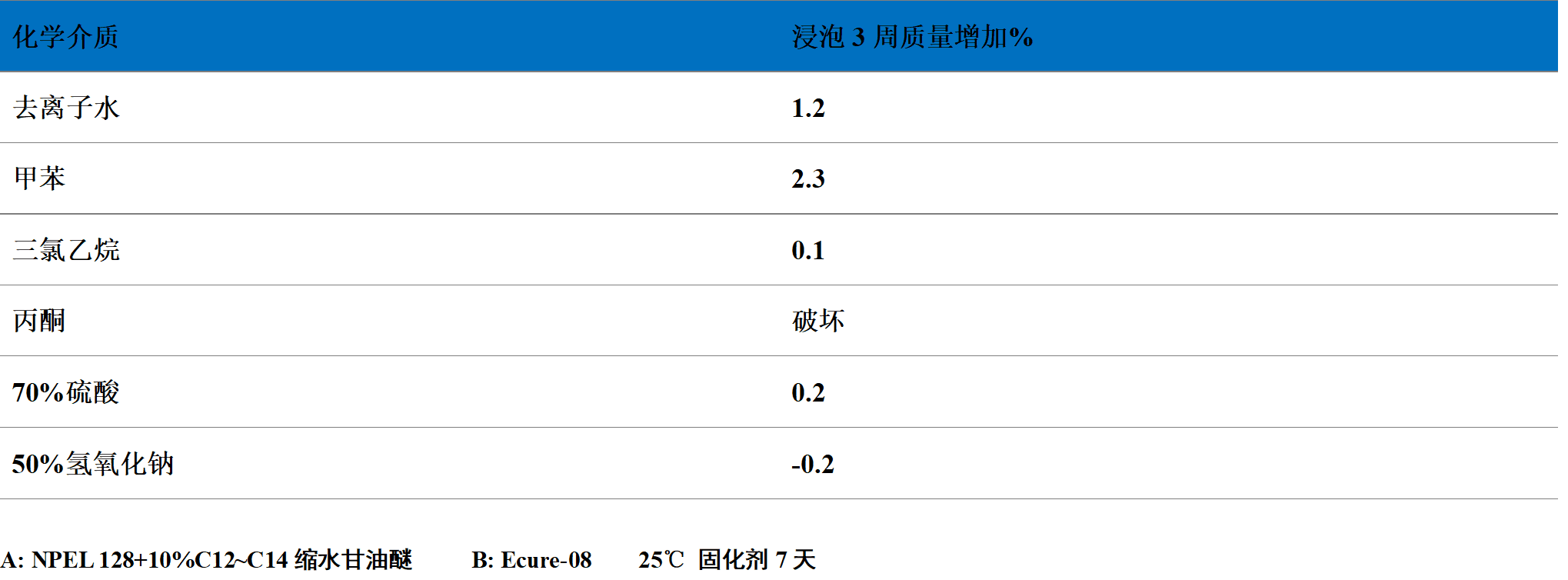

Chemical Resistance Test Results (Ecure-08 after 3-week immersion)

Test Conditions: NPEL 128 Epoxy Resin + 10% C12-C14 Glycidyl Ether / Ecure-08 Curing Agent, Cured at 25°C for 7 Days

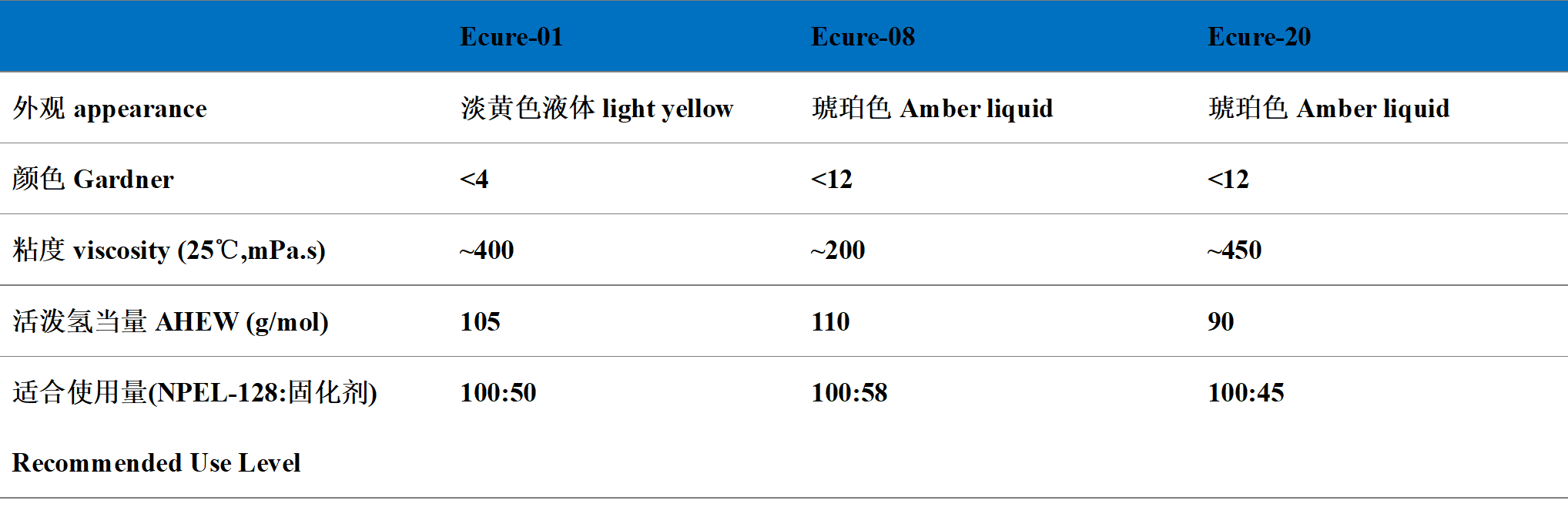

Physical Properties

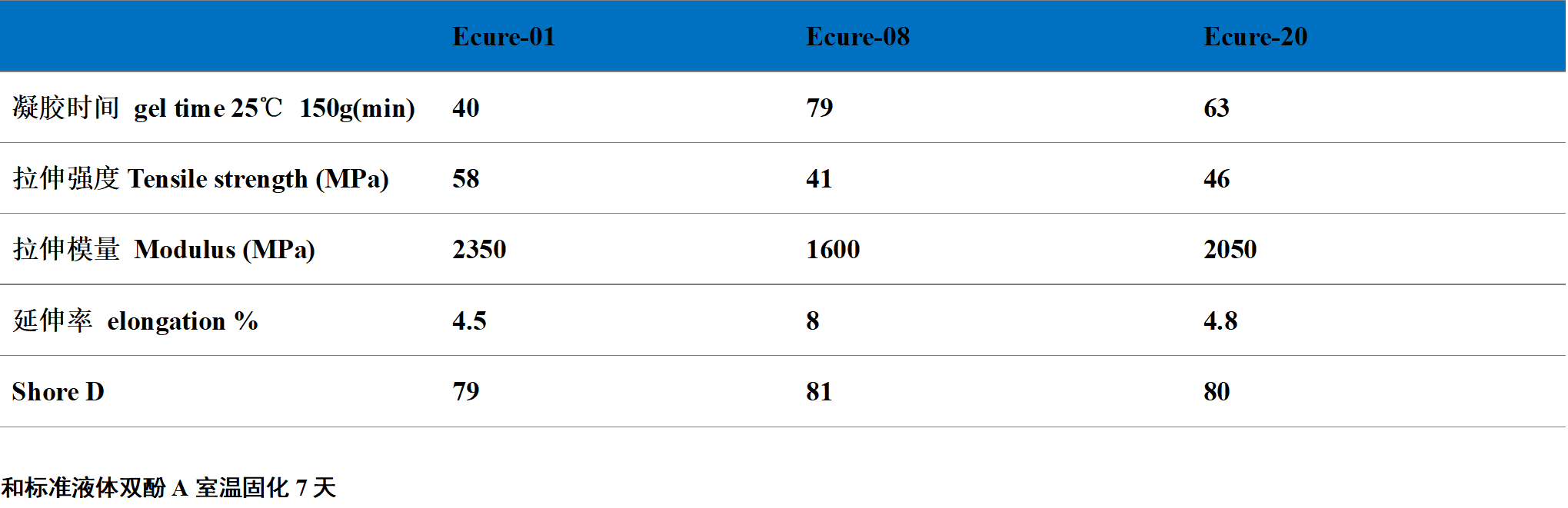

Cured Properties (Typical Values)

Storage & Handling

- Shelf Life: Minimum 12 months from production date when stored in original sealed containers at ambient temperature.

- Storage Conditions: Store in a cool, dry, well-ventilated area away from direct sunlight, heat sources, and moisture. Keep containers tightly sealed when not in use.

- Handling Precautions: Wear appropriate personal protective equipment (PPE) as recommended in the Material Safety Data Sheet (MSDS). Avoid contact with skin, eyes, and clothing. Ensure adequate ventilation during use.

- Safety Information: Refer to the MSDS for detailed safety, handling, and disposal instructions.

Compliance

- Complies with REACH and RoHS regulations.

- All products are tested to meet international quality and safety standards.