Aromatic amine epoxy curing agents are compounds containing aromatic rings and amino groups (-NH₂) in their molecular structure. They undergo a ring-opening reaction with epoxy groups in epoxy resins through amino groups to form a three-dimensional network structure, transforming epoxy resins from liquid or solid state into cross-linked cured products with high strength and hardness. The following is a detailed introduction to modified aromatic amine epoxy curing agents designed for specific scenarios:

Product Overview

This modified aromatic amine epoxy curing agent is specially developed for composite material pipeline winding processes. It is suitable for:

- Petroleum/natural gas pipelines

- Chemical pipelines

- Industrial pressure vessels

Product Features

| Feature | Advantage |

|---|---|

| ⏳ Long operating time | Suitable for complex winding processes |

| 💪 High strength and toughness | Resistant to internal pressure and impact loads |

| 🌀 Low viscosity (300-500cPs) | Excellent fiber wetting property and resin fluidity |

| 🧪 Chemical corrosion resistance | Suitable for conveying corrosive fluids |

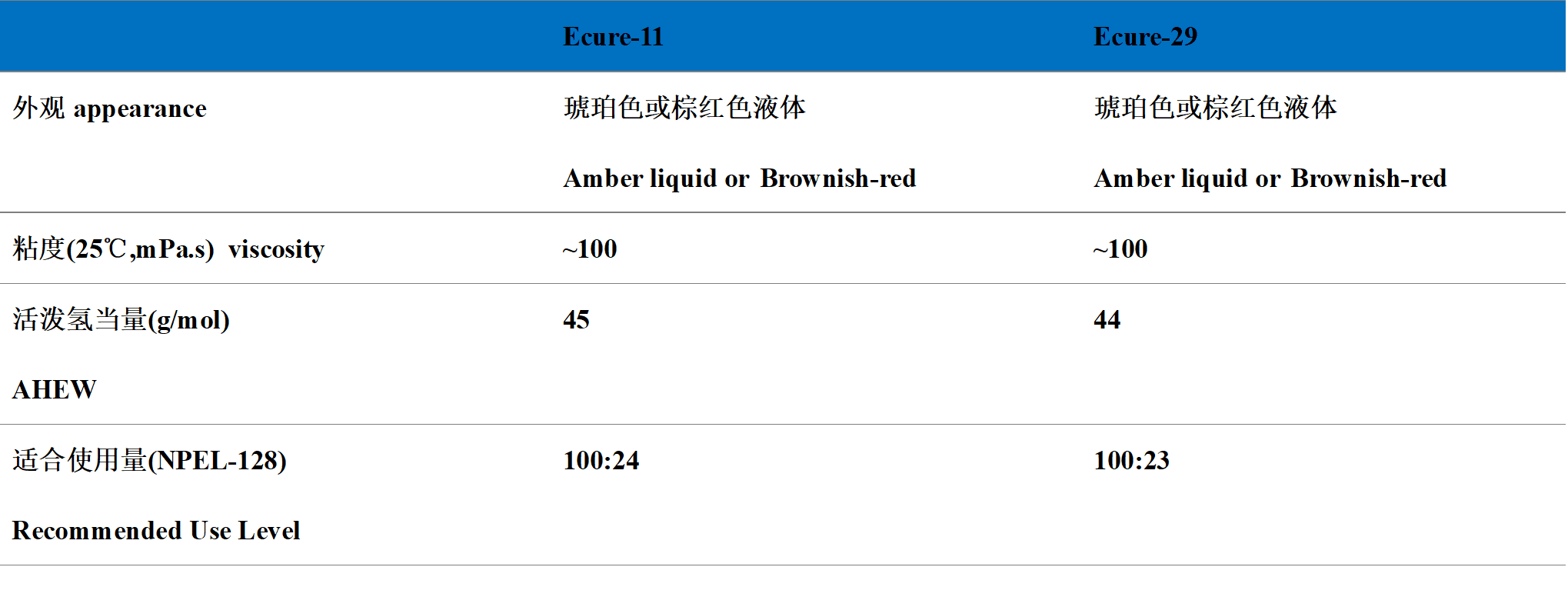

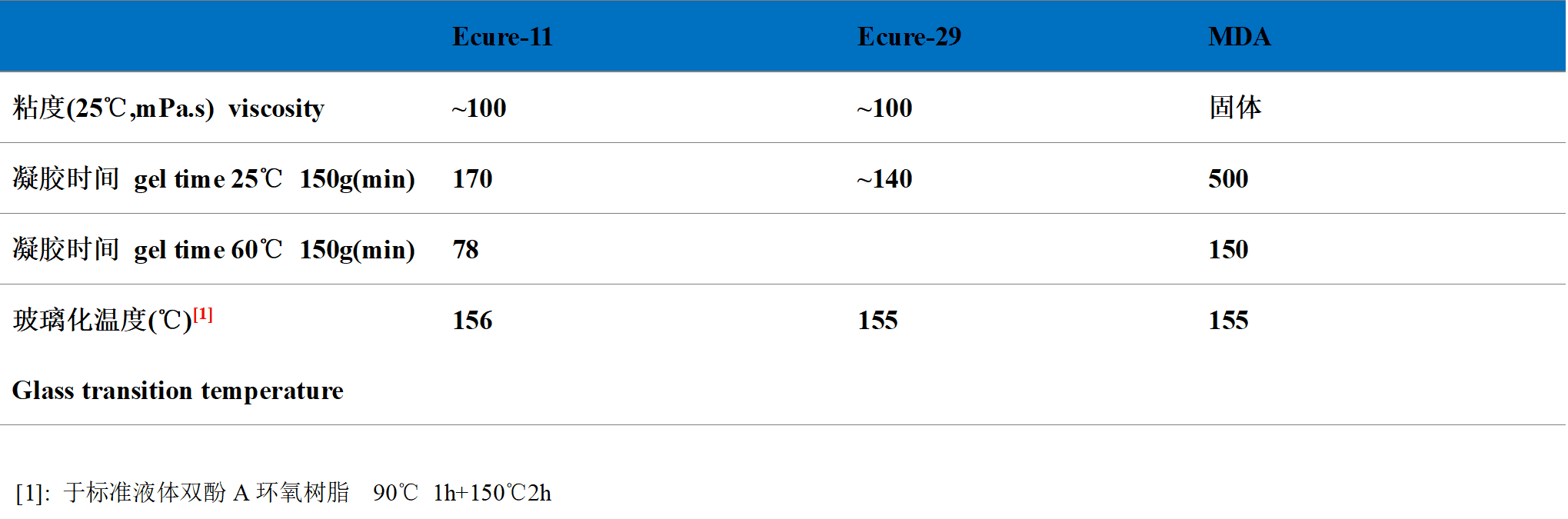

Technical Parameters

Basic Performance

Post-Curing Performance

Storage and Handling

- Shelf life: 24 months in unopened containers

- Storage temperature: 15-30℃

- Moisture protection: Keep containers sealed

- Crystallization treatment: If crystallization occurs, heat to 60-80℃ to melt Safety Tips:

- Please read the MSDS before use and wear PPE (Personal Protective Equipment).

- Contains amine compounds; avoid direct s