Testing Principle

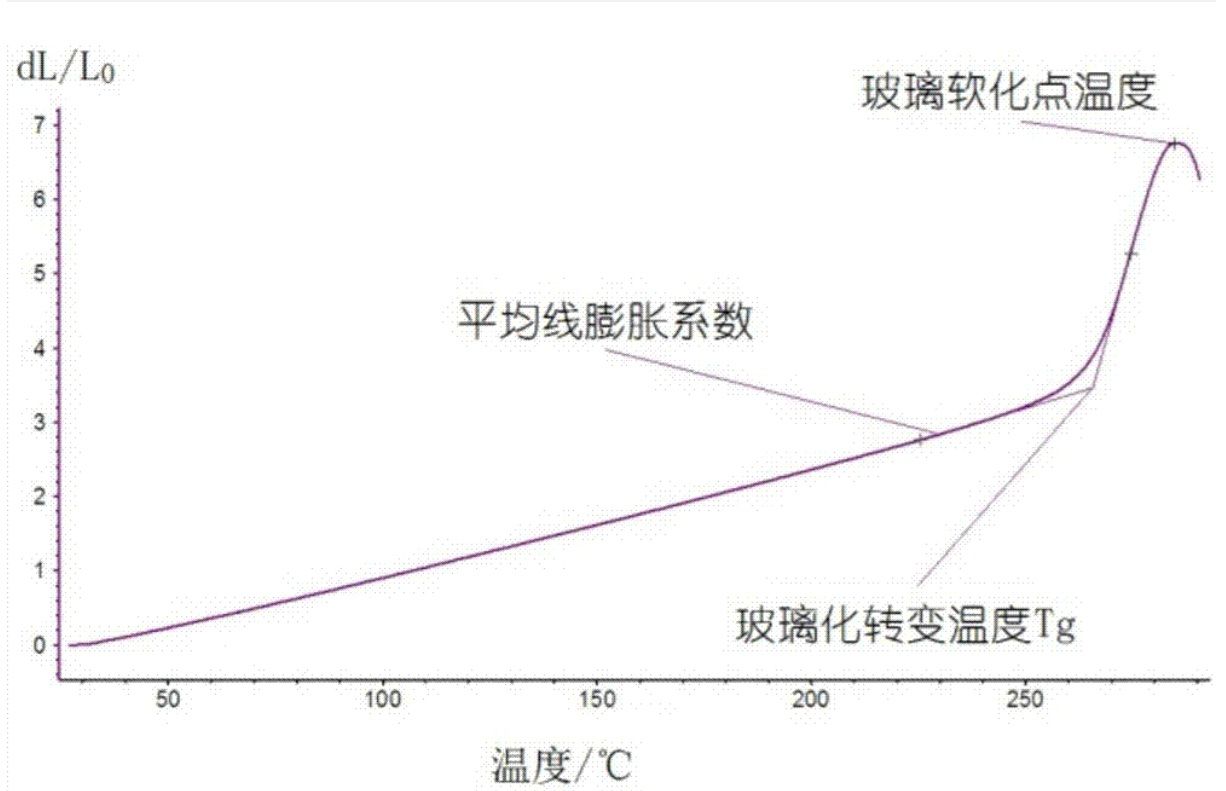

In accordance with the provisions of GB/T 36800.3-2025, the penetration temperature refers to the temperature corresponding to when a probe of specific specifications penetrates a plastic sample to a preset depth under a constant load under the test conditions specified in this standard. Essentially, this indicator reflects the changes in the mechanical properties of plastic materials as the temperature rises. When the temperature reaches a certain threshold, the rigidity of the material decreases, the plasticity increases, and it can no longer resist the penetration force of the probe. The temperature at this time is the penetration temperature.

Testing Method

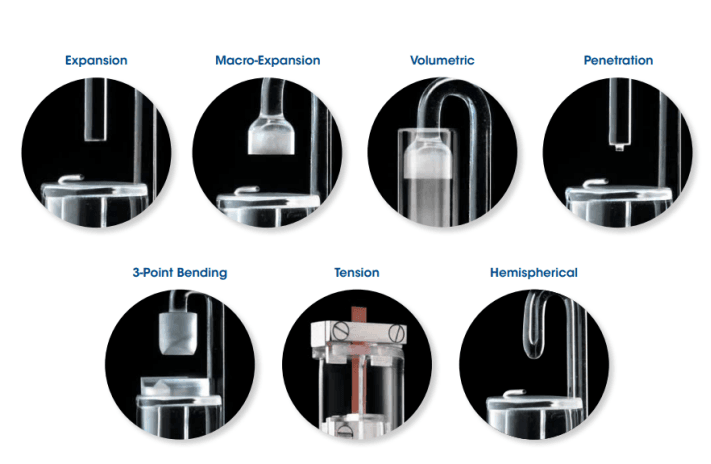

Static Thermomechanical Analysis (TMA) Method

Testing Parameters

Sample Preparation

The sample shall be a uniform and flat sheet material with a thickness usually ranging from 0.5mm to 4mm (the specific thickness can be adjusted according to the material characteristics, but it shall be indicated in the test report). The surface of the sample shall be free of defects such as scratches, bubbles, and impurities; for non-sheet materials, they shall be processed into samples that meet the requirements.

Conditioning

Before the test, the sample shall be placed in standard environmental conditions (temperature: 23℃±2℃, relative humidity: 50%±5%) for at least 40 hours to eliminate internal stress and humidity differences of the sample and ensure the consistency of the test state.

Heating Rate

The standard recommended heating rate is 5℃/min. For special materials, it can be adjusted as required, but it shall be explained in the test report.

Load Magnitude

Select an appropriate load according to the hardness and application of the material. Common load values are 1N, 2N, etc. The load shall be stably applied to the probe before the start of the test.

Sample Submission Requirements and Notes

The sample shall be a uniform and flat sheet material with a thickness usually ranging from 0.5mm to 4mm (the specific thickness can be adjusted according to the material characteristics, but it shall be indicated in the test report). The surface of the sample shall be free of defects such as scratches, bubbles, and impurities.

Test Example

Reference Standard

GB/T 36800.3-2025 Plastics - Thermomechanical Analysis (TMA) - Part 3: Determination of Penetration Temperature