EP-FL1, Ecflex-07, and Ecflex-10 are suitable for ultra-flexible elastic epoxy adhesives. This product features adjustable elasticity and maintains excellent flexibility even at low temperatures. It exhibits silicone-like flexibility combined with epoxy bonding strength, corrosion resistance, and resistance to damp heat. EP-FL1 is a special-structure epoxy resin, while Ecflex-07 and Ecflex-10 are modified amine curing agents. The product contains no plasticizers.

Product Features

- Low-temperature elasticity

- Excellent resistance to thermal shock and heat aging

- High bonding strength

- Complies with REACH and ROHS requirements

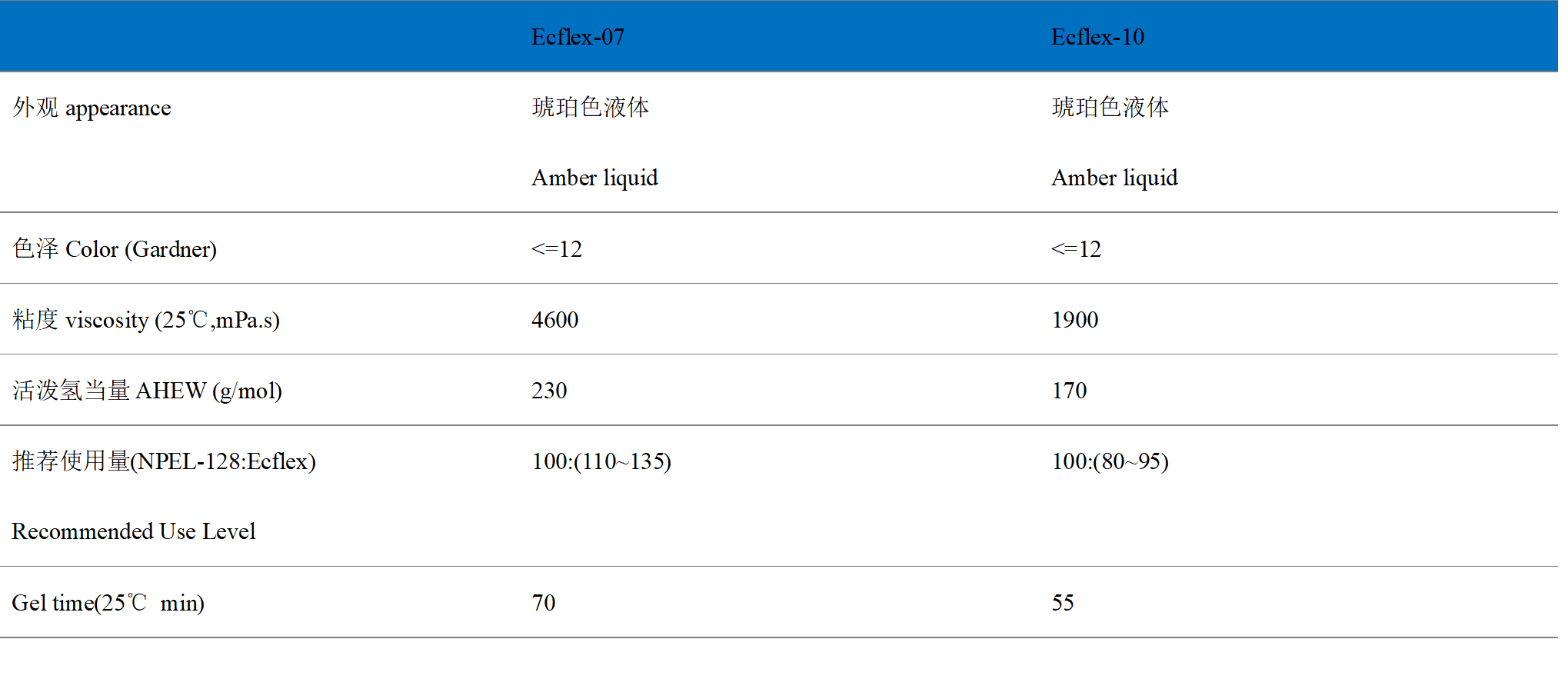

Typical Product Properties

Typical Applications

- Electronic adhesives and electrical potting compounds requiring high resistance to thermal shock and damp heat aging

- Thermal conductive adhesives for automotive batteries, gap fillers for battery packs

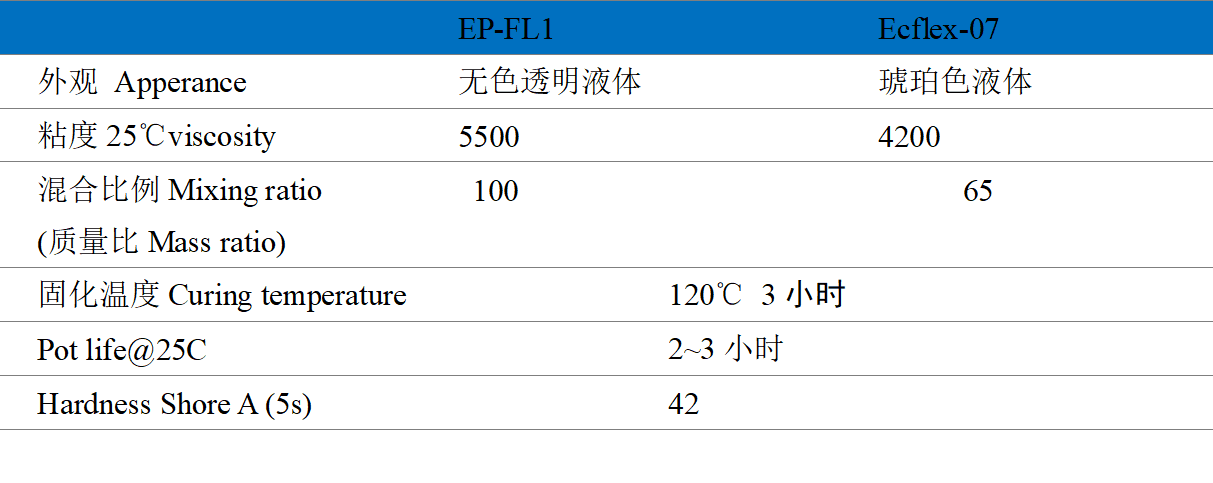

Reference Formulation and Performance (Epoxy A/B two-component system available):

| Parameter | EP-FL1 | Ecflex-07 |

|---|---|---|

| Appearance | Colorless transparent liquid | Amber liquid |

| Viscosity at 25°C (mPa·s) | 5500 | 4200 |

| Mixing Ratio (mass ratio) | 100 | 65 |

| Curing Temperature | 120°C for 3 hours | |

| Pot Life @ 25°C | 2-3 hours | |

| Hardness Shore A (5s) | 42 |

Storage and Subsequent Treatment Methods

- Please refer to the MSDS

Shelf Life and Storage Conditions

- Minimum 24 months from the date of production

- Store in a sealed container in a cool, dark, and dry environment. Avoid prolonged exposure to air and moisture.

- Crystallization may occur at low temperatures. Heat to 60-80°C to melt before use; the product will function normally after melting.